Recycling of different catalyst materials

Many treasures are hidden in scrap metal. In collaboration with our customers, we ensure that they are reintroduced into the resource cycle. Be it vehicle catalysts on metal or ceramic basis, diesel particulate filters, or industrial catalysts. We achieve the very best recovery quotas possible through individually tailored recycling strategies.

We cut the ceramic catalysts with industrial sized alligator shears. The precious metal monolith is then broken up and ground into a homogenous powder. In order to prevent even the slightest loss of material, all dust is returned to the processing cycle. We take a series of small monolith powder samples for an accurate precious metal content analysis in our lab. The monolith powder is cast into collector metal in our metal workshop.

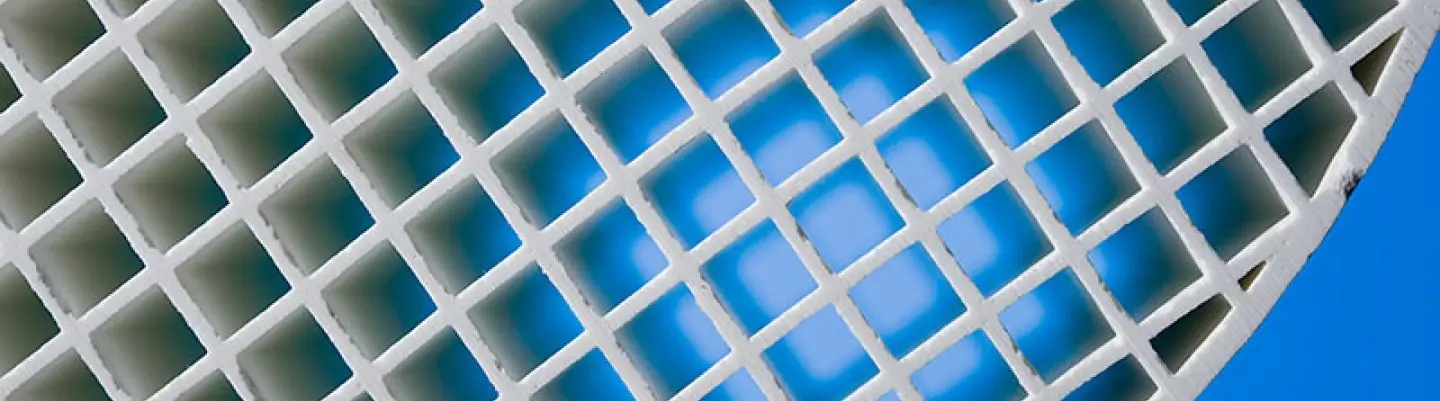

Metal catalysts end up in the recycling process in ever increasing numbers. They offer an alternative to ceramic catalysts not only in vehicles but in numerous other fields of application as well. The comparatively small thickness of their cell walls, achieved through the usage of spiral shaped metal foils and stacked plates as carriers for the precious metal coating, is only one of their numerous advantages.

ReMetall has developed a highly refined procedure, which, through clean separation, allows for significantly above average recovery quotas. We open the catalyst’s casing by hand to extract the precious metal coated foil. The foil is cut into pieces and ground into a fine powder. We extract all precious metal content via suction during the grinding process and create a homogenous metal powder. Following the extraction of probes for value analysis, the material is sent to the refiner for the final processing stage.

Catalysts have numerous industrial applications in both emission purification and production. They are as essential in the realm of Bio-fuel production and environmental technology as in Oil refinement and the chemical industry.

The shapes and sizes of industrial catalysts are just as numerous and diverse as their fields and application. To ensure the highest recovery quotas we choose the recycling method most suitable for each individual catalyst, and as such provide a closed precious metal cycle.

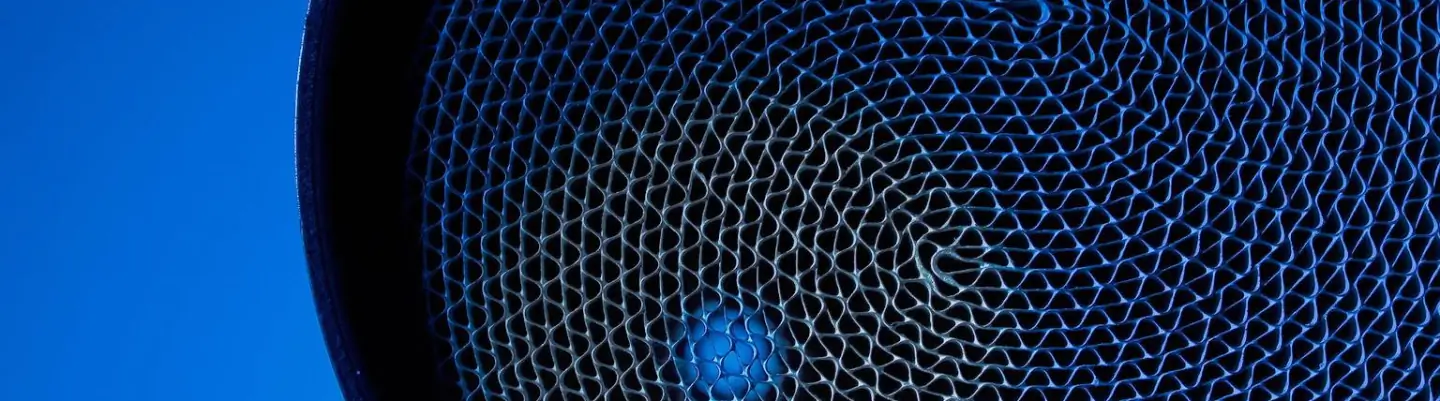

Particulate filters reduce the amount particles in the emission of Diesel engines. They are based on a ceramic honeycomb structure, most often coated with an amalgamation of precious metals. After some time the filter is clogged with ashes and soot and has to be replaced.

We asses the precious metal content of the filters and subject them to a procedure similar to that of the ceramic catalysts, ensuring efficient recycling with minimal losses.